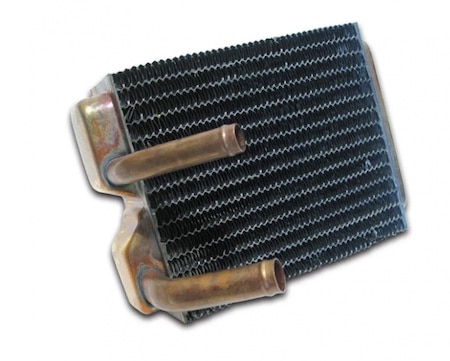

Its usually a tough job to replace a heater core. I recently pulled my heater core out and set out to try and find a replacement heater core made of brass and copper and was not be able to find one. The only heater cores that seem to be readily available are aluminum!

This leads to a simple question:

Are Aluminum Heater Cores Better than Copper/Brass Heater Cores?

Current aluminum heater cores are more efficient than old style heater cores. Despite copper being a better conductor of heat, newly designed heater cores allow for more efficient heat transfer. Because of slightly better heat transfer rates and less material required, aluminum heater cores are used instead of brass.

Aluminum is the “better” material for heater cores because with better designs than old style brass heater cores, the heat transfer capability is able to be matched and it is a simple matter of less aluminum material is required than brass.

Aluminum heater cores are cheaper, and can potentially transfer heat just as well as the brass heater cores, so they are considered better! For these reasons copper heater cores have been phased out and are not easily available. Aluminum heater cores are used now instead of brass/copper because aluminum is cheaper achieving comparable cooling results.

Heat Transfer of Copper vs Aluminum Heater Cores

Copper transfers heat more than 1.5 times faster than aluminum, but heater cores are made of brass which is zinc added to copper. Heater cores are often constructed with some components copper, and some brass, so the overall average thermal conductivity of the material used in heater cores is somewhere in between.

| Material | Thermal Conductivity Coefficient (W/m*K) at 20 degrees Celsius |

| Copper | 386 |

| Brass (60/40) | 96 |

| Aluminum | 239 |

Pros and Cons of Copper vs Aluminum Heater Cores

A reason that brass heater cores may be considered better by some is because they are easier to repair. Brass heater cores can be soldered and simply repaired while aluminum heater cores are difficult and expensive to repair.

Another concern is the effect of corrosion in the cooling system from different materials. But that we will address later in this article.

The reason aluminum heater cores can match the heat transfer capability of old copper heater cores is the redesign of heater cores. More points of contact inside of the heater core and more tubes for heat transfer in the same amount of space allows aluminum heater cores and radiators to work at least just as efficiently and use less material.

Should I continue searching for a copper replacement heater core or simply go with the aluminum heater core?

Replace your old brass heater core with a new aluminum replacement. Current aluminum heater cores are designed with enough efficiency to match the heat transfer capability of your old brass heater core. One of the only reasons to consider using a brass replacement is to keep the car 100% factory. It is possible to find them.

A good place to start if you cannot order a heater core at your local parts store is by contacting BrassWorks where they can custom make heater cores out of brass/copper.

Some car enthusiast refuse to use the aluminum because they seem to be more cheaply made. For that reason alone they choose not to use them. Which is a fair argument. If it seems cheaply made, then make the effort to find one that is well made. It will be worth the extra time and dollars in the long run. Not all aluminum heater cores are cheaply made.

Aluminum heater cores are readily available and can be purchased for extremely cheap. For myself, this was one of my reservations to using an aluminum heater core. Since it is so cheap I assumed it must be cheaply made. And it may be. I imagine that a cheap aluminum replacement is not going to last 30 years like your old brass heater core.

But it may last 25, so for many the extra 5 years or so may not be worth paying a premium for a new brass heater core.

In fact, what the deciding factor for me was, was that most, if not all modern cars are made with aluminum heater cores now. Yes, your old heater core lasted a VERY long time, but so will the new aluminum heater core. Just chuck it in and be done!

Differences Between Copper and Aluminum Heater Cores

What is the Difference Between Aluminum and Copper/Brass Heater Cores?

Copper was the material of choice for many many years for both heater cores and radiators.

The price of the material was low enough, it is a soft and durable material, and transfers heat well. Lead solder was used for the copper heater cores, which does not transfer heat nearly as well as copper, but the ease at which a cracked heater core could be repaired was the major upside that resulted in deciding on using copper.

Radiators today as well as heater cores have been redesigned well enough to result in aluminum radiators and heater cores transferring heat just as quickly as the copper/brass heater cores. The new design features include things like thinner wider tubes that allow for more rows of tubes to be constructed into the same amount of space.

There is a slight concern of electrolysis and corrosion that can occur inside of the cooling system and if that is affected by the use of aluminum vs copper. That is addressed right after mentioning the common misconception of a brass vs copper heater core.

Why are Aluminum Heater Cores Replacing Copper Heater Cores?

The price of aluminum to make a heater core that can perform just as well as a copper heater core is lower, making aluminum the obvious choice for the manufacturers.

What is the Difference Between Copper and Brass Heater Cores?

Brass is simply copper and zinc mixed together. Together they form an alloy called brass.

Brass heater cores and copper heater cores are the same thing.

The term “brass heater core” and “copper heater core” can be used interchangeably because they are made of both brass and copper. A heater core cannot be made of purely copper because it would be too soft. Brass (with the addition of zinc) makes the core stronger.

Brass often consists of somewhere between 60% copper and 40% zinc to 80% copper and 20% zinc.

Will Electrolysis occur more in an Aluminum or Copper Heater Core

To give the short answer..

An aluminum radiator or heater core will not corrode faster than one made of copper. A heater core made of copper will corrode at least if not more quickly than one made of aluminum because of the lead solder joints in the copper.

Basically we are more concerned with the neighboring materials and if there is copper and aluminum together in the cooling system, then the aluminum will corrode faster, but if they are alone then it does not make a significant difference, and there is not going to be more galvanic corrosion with an aluminum radiator or heater core.

To learn the long answer, read this very well written article on a metal expert site called Windo Metal.

Are Aluminum Heater Cores any good?

To sum up the discussion on aluminum vs copper heater cores: Are aluminum heater cores any good?

Aluminum heater cores are good enough for all modern cars to equip them from the factory. They transfer heat just as well as an old copper heater core and can be a worthy replacement. The most important factor to look for when installing a new heater core is the quality of the manufacturer.

Ensure that the manufacturer is reputable and it is almost always worthwhile to pay a few extra dollars to get the reputable manufacturers product over a cheap knockoff. If in a case where a copper heater core was available, I would get whichever was made by the better manufacturer. Otherwise, take the one that you can get and install it and be done!