Lug nuts can be a challenge to tighten. Tire shops can damage them by using an air wrench. You can damage them by hand if they are too loose. Easily tightened too much can also be damaging. So many questions! Here are the answers.

How Tight Should Wheel Lugs Be?

After calling 20 different tire shops, these are the results of asking them “How tight do you torque lug nuts?”:

The average torque value used by tire shops on a mid-size vehicle is 85 ft-lb. The surveyed results were very close amongst all the shops. Some shops torque the wheels to 80 ft.-lbs. While some torque them to 90 ft.-lbs. Some tire shops even admitted that they just use an impact wrench to tighten lug nuts but aim for 90 ft.-lbs.

Consulting the repair manual for your vehicle will provide the exact lug nut torque specifications. Later we will include some other ways to estimate the required torque and

Not everyone has a top-of-the-line torque wrench like the tire shops do though so follow along to get the answers to the biggest questions about wheel lugs including finding out the best way to tighten them by hand.

Some Vehicles Lug Nuts Require More Force

Besides just using the average torque valueAnother way to gauge it and the way most tire shops use it by number of lugs and the size of the studs. Bigger vehicles will have larger wheels and bigger wheel studs. Smaller cars will have fewer and smaller wheel studs.

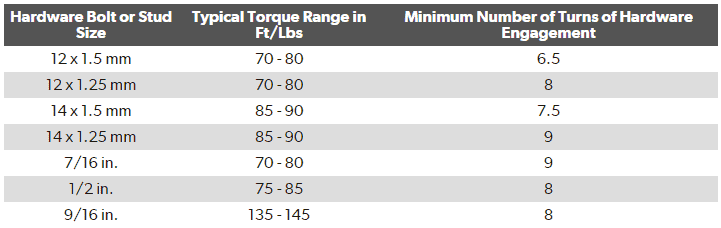

A chart such as this indicates the torque based on the size of the wheel stud

Tightening Lug Nuts by Hand WITHOUT a Torque Wrench

The risk of tightening lug nuts by hand without a torque wrench is that the lug nuts can be easily under-tightened allowing for the possibility that the wheel could come loose. Likewise the wheel can easily be severely overtightened causing damage to the wheel studs becoming a safety hazard.

Tighten your wheels with more consistent and accurate results by hand without a torque wrench by exerting force in the same place onto a tire iron. Press downwards on the tire iron about 1 foot away from the wheel stud and press with a percentage of your body weight equivalent to roughly 90 pounds.

90 foot-pounds is a good average force to torque your lug nuts to for your vehicle if you own a sedan or mid size SUV.

Try to gauge the amount of body weight that you need to lean on the tire iron. For example, if you weigh 150 pounds then you should apply 60% of your body weight to the tire iron to achieve a force of 90 ft.-lbs.

Again if you are pushing on the tire iron 1 foot away from the wheel stud! The amount of force applied to the lug nut increases with the same pressure applied along a 2 foot bar as opposed to a 1 foot bar.

By pressing downwards, you eliminate the pulling motion which can be more difficult to gauge than using your body weight. Also avoiding pulling on the bar further than 1 foot down the bar will prevent much of the possibility of over tightening.

Tightening Lug Nuts by Hand WITH a Torque Wrench

Using a torque wrench is the proper way to tighten lug nuts. Start by tightening the lug nuts in a star pattern to slightly more than hand tight to seat the wheel while it is still on the jack stands. Lower the car, and then use the torque wrench in a star pattern to tighten the lug nuts to 90 ft.-lbs.

Tighten Lug Nuts in Star-Pattern

Star-pattern sequence is alternating sides of the wheel or thing you are tightening in a fashion that follows the pattern of a star. By tightening in a star pattern, you reduce the risk of warping the surface or seating the wheel improperly.

Hand tighten all of the lug nuts together, then use a rachet alternating opposite sides of the wheel until all have been tighened.

Final torque can then be performed being careful to adjust your torque wrench to the right setting. Too many times I have seen torque wrenches that are miscalibrated, tough to read, and easily loosen when they shouldn’t. For anything that requires it tightened to a certain specification, a good torque wrench is a must have and should be taken seriously.

After spending hours searching for a good quality USA made torque wrench at a reasonable price point, I found and personally own, use, and recommend this 3/8″ drive Proto torque wrench on Amazon. I have used it for years and expect it to last a lifetime.

Should you use Anti-Seize or oil on wheel studs?

No lubricant should be used on wheel studs. Anti-Seize is not recommended for use on wheel studs because of its nature to drastically alter the tightening effects of the lug nuts while installing the wheels. By using Anti-Seize, it may cause improperly tightened wheels and they should be installed dry.

Oil should not be applied to wheel studs. Oil will alter the reading of torque force applied to the lug nut causing an over tightened lug nut. This can result in damage to the wheel studs and wheels should be installed dry without the use of any lubricant.

What Causes Lug Nuts to Keep Coming Loose?

Before applying Loctite or taking any other extra measure to keep your wheel in place, do a thorough inspection of the wheel, hub, and the wheel studs. Most likely you will find something worn enough to need to replace. New wheels do not just come loose after being torqued properly. Something is worn out.

Lug nuts may continue to come loose due to being under tightened, over tightened damaging the wheel studs or wheel, or improper seating of the wheel to the wheel hub. The wheel should be removed and inspected for abnormal wear on the wheel, studs, rotor, or hub.

If you have tried multiple times tightening the wheel lugs to spec and still have wheels coming loose, replace the wheel studs and rotor. Most likely at one point they were overtightened and became stretched out. Now, with the threads stretched slightly they are unable to remain tightly in place.

Another cause of lug nuts continually loosening is the use of lubricant on wheel studs. Lubricant should not be used on wheel studs.

What Happens if you Drive with Loose Lug Nuts?

You will be able to notice your wheel coming loose because of a wobbling bumpy feeling while driving the car. Eventually the wheel will work its’ way loose and fall off. It can be catastrophic at high speeds while at low speeds generally a few of the wheel studs will shear and the wheel will become lodged in the wheel well.

Do not continue to drive the car and either jack it up and tighten the wheel, or call AAA and have your car towed to a shop right away.

The expense and inconvenience will be much cheaper and more convenient than the damage that occurs if your wheel falls off.

How Tight Should Spare Tire Lug Nuts Be?

Occasionally finding the torque specs for the spare tire lug nut can be difficult.

I have searched for this value for more than a dozen vehicles and have found a good average torque specification that can be used without being concerned of causing damage or loosing your spare wheel.

The average torque specification for spare tire lug nuts is tighten to a force of 60 ft.-lbs. Most car manufacturers recommend a tightening specification of 40-80 ft.-lbs. Spare tires should certainly not be tightened as tight as a regular wheel lug.

A Jeep is one of the more common vehicles to have a spare tire secured to the back of the car but this specification works for Land Rovers, 4Runners, and any other vehicle with a spare tire on the back.

How tight should a Jeep Wrangler spare tire lug nut be tightened?

The torque specification for the spare tire lug nut is 40-80 ft.-lbs. Most other mid-size and full-size vehicles do not recommend a torque specification greater than 80 ft.-lbs. The spare tire does not need to be bolted on as tightly as the regular wheels.

A good reference for this spec. for a Jeep is this link Project-JK.com. Click to open the Jeep manual and the specification is printed about 3/4 of the way down the pages.

I have torqued spare wheels to no more than 60 ft.-lbs. for years and have never ever had one come loose.

Local car mechanic shop manager

Spare tires are simply not under the same stresses that the main tires are. You can rest assured by tightening them to 40-60 ft.-lbs.